Plastics Rotomolding in Automotive: Lightweight Solutions for Vehicles

Plastic-type material manufacturing has grown to be a crucial part of several industries. It offers made great contributions to different fields, such as automotive, underwater, agriculture, and more. With all the improvement in technology, distinct processes of plastic-type developing emerged. Just about the most impressive and Rotomolding stylish ones is rotomolding, which includes revolutionized the plastic materials industry. In the following paragraphs, we will check out everything you should understand about the rotomolding method.

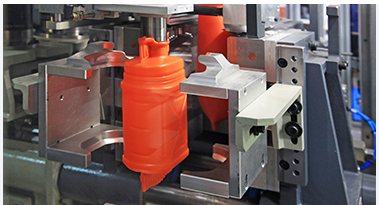

Rotomolding is undoubtedly an innovative method used to create intricate plastic-type merchandise. It demands molding the plastic by warming and rotating it, letting it distribute evenly over the mildew area. This process is extremely specific and generates great-top quality merchandise with outstanding style overall flexibility. Rotomolding is useful for producing intricate styles and intricate types of plastic-type material merchandise.

A single significant benefit from rotomolding is it can create products with effortless, standard wall space. Consequently the products’ size and durability are constant, which leads to high-good quality merchandise. Another benefit of rotomolding is it can produce items of varied styles and sizes, that makes it a popular selection for diverse market sectors.

Additionally, rotomolding can use different kinds of thermoplastics. Polyethylene is considered the most commonly used thermoplastic from the rotomolding procedure due to the outstanding qualities like toughness, substance opposition, and suppleness. Furthermore, rotomolding is surroundings-friendly since it employs no solvents or paints to create merchandise.

Yet another substantial good thing about the rotomolding process is its cost-effectiveness. In comparison to other plastic molding procedures, the tooling and equipment expense in rotomolding is pretty reduced. The simplicity from the method, subsequently, cuts down on the creation expenses. This advantages will make it a popular option for smaller businesses and initiate-ups trying to create substantial-good quality plastic-type material items.

Lastly, rotomolding also reduces waste materials by facilitating the reuse of your uncooked fabric in the manufacturing approach. Contrary to other molding functions, rotomolding can produce different goods from just one fungus, lowering the necessity for substance transform for each and every merchandise. This decreases the spend made during the production procedure.

In short:

In In short, rotomolding is actually a groundbreaking procedure that has significantly impacted the plastic-type manufacturing business. It includes several advantages including the power to produce complex models, durability and persistence, expense-effectiveness, and enviromentally friendly friendliness. As a result of these benefits, it is a common option for making plastic material goods across distinct businesses. When you are thinking about production plastic material goods, rotomolding ought to be the best option.